Definitions and Basic Principles

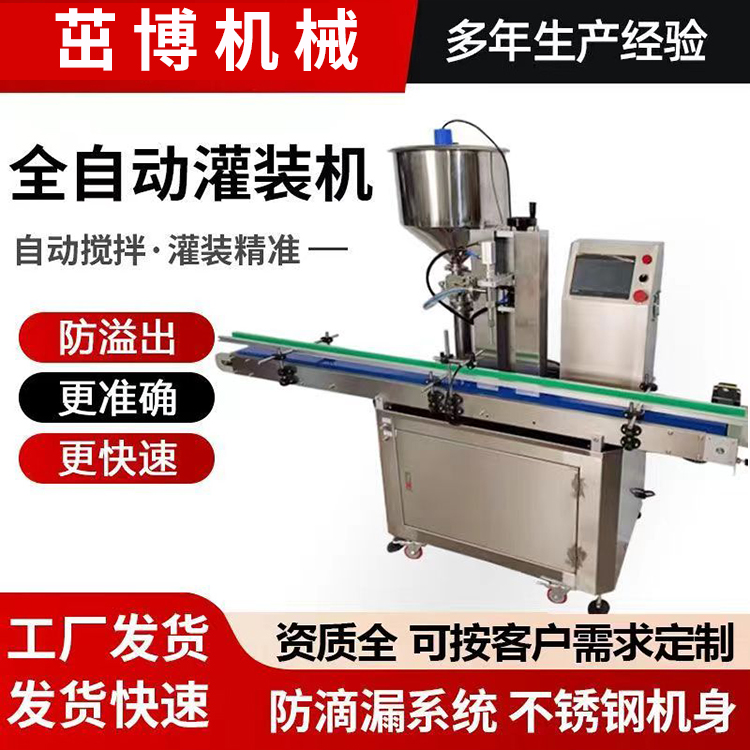

The fully automatic rotary pump filling machine is a liquid filling equipment with a relatively high degree of automation. It mainly relies on the rotary pump to achieve the transportation and filling of liquids. Inside the rotary pump, there is a pair of rotors that rotate synchronously in opposite directions. During the rotation process, the liquid is sucked in and discharged by relying on the volume change of the closed chambers formed between the rotors and the pump body. When the motor drives the rotors to rotate, the liquid is sucked into the pump chamber and then carefully filled into the container through the filling head under pressure.

Main Components and Functions

It includes conveyor belts and positioning devices, etc. The conveyor belt transports empty containers to the filling position and, after the filling is completed, transports the filled containers to the next process. The positioning device ensures that the containers can be accurately aligned with the filling head during the filling process, improving the filling accuracy.

It realizes the automated operation of the equipment. Through preset programs, parameters such as filling volume, filling speed, and filling time can be controlled. At the same time, the running status of the equipment can be monitored. For example, when a fault occurs, it can promptly alarm and stop the machine to protect the safety and stability of production.

It is used to carefully fill the liquid into the container. Its design can be adjusted according to different container shapes and sizes to ensure that the liquid can be accurately injected without liquid splashing or overflowing. Some excellent filling heads also have an anti-dripping function, which can effectively prevent liquid residue from dripping after the filling is completed.

This is the core component responsible for the extraction and transportation of the liquid. Its special rotor structure enables it to handle liquids of various viscosities, applicable to everything from low-viscosity beverages to high-viscosity sauces, glues, etc. Moreover, it has good self-priming ability and can suck the liquid into the pump chamber without the need for external auxiliary devices.

Rotary Pump:

Filling Head:

Control System:

Conveyor System:

Product Features

It adopts a modular design with a reasonable layout of each component. When a certain component fails, maintenance personnel can conveniently carry out inspection, repair, and replacement. Moreover, the daily cleaning and maintenance of the equipment are also relatively easy, reducing the maintenance cost of the equipment.

It generally has a user-friendly human-machine interaction interface. Operators can master the operation method of the equipment through simple training. Various parameters such as filling volume and filling speed can be set on the touch screen, and the running status of the equipment can be viewed in real time.

It is applicable to various types of liquids. Whether it is a low-viscosity liquid like water or a high-viscosity liquid with solid particles like jam, it can perform excellent filling. At the same time, it can also adapt to containers of different shapes and sizes, such as glass bottles, plastic bottles, metal cans, etc.

With the help of an excellent metering system and control system, it can accurately control the filling volume. The filling error can be controlled within a small range. For some products with strict dosage requirements, such as pharmaceuticals and lubricating oils, it can ensure that the amount of liquid in each container meets the standard requirements.

It can achieve continuous filling at an appropriate speed. Compared with manual or semi-automatic filling machines, its filling speed can be significantly increased, thus meeting the needs of large-scale production. For example, on a beverage production line, dozens or even hundreds of bottles of beverages can be filled per minute, greatly improving production efficiency.

Efficiency:

Accuracy:

Wide Adaptability:

Simple Operation:

Convenient Maintenance:

Application Industries

It plays a role in the filling of chemical products such as coatings, lubricating oils, glues, and pesticides. For example, for corrosive coatings, the rotors and stators are made of corrosion-resistant (subject to the actual report) materials, which can adapt to requirements such as viscosity, fluidity, and corrosiveness, protecting the filling accuracy and efficiency.

It can be used for the filling of cosmetics such as emulsions, creams, shampoos, and bath gels, accurately controlling the filling volume to make the packaging look good. In the filling of detergents, it meets the requirements of large filling volume, good efficiency, and stability. It can also perform excellent filling for high-viscosity toothpaste.

It can carefully fill various pharmaceuticals such as oral liquids, injections, and eye drops. It can also evenly fill semi-solid foods such as ointments and can control the filling speed and pressure to avoid problems such as food layering and bubbles. In the filling of traditional Chinese medicine decoctions, it can adopt a gentle method to maintain the quality of the decoctions.

It is used for the filling of liquid beverages such as carbonated beverages, fruit juices, and tea beverages, ensuring that the capacity of each bottle of beverage meets the standard. In the filling of alcoholic beverages, it can achieve accurate quantitative filling, ensuring that the liquor is not wasted and that the contacting parts meet the hygiene standards. It can also well complete the filling tasks for products such as sauces, edible oils, and dairy products.

Food and Beverage Industry:

Pharmaceutical Industry:

Daily Chemical Industry:

Chemical Industry: