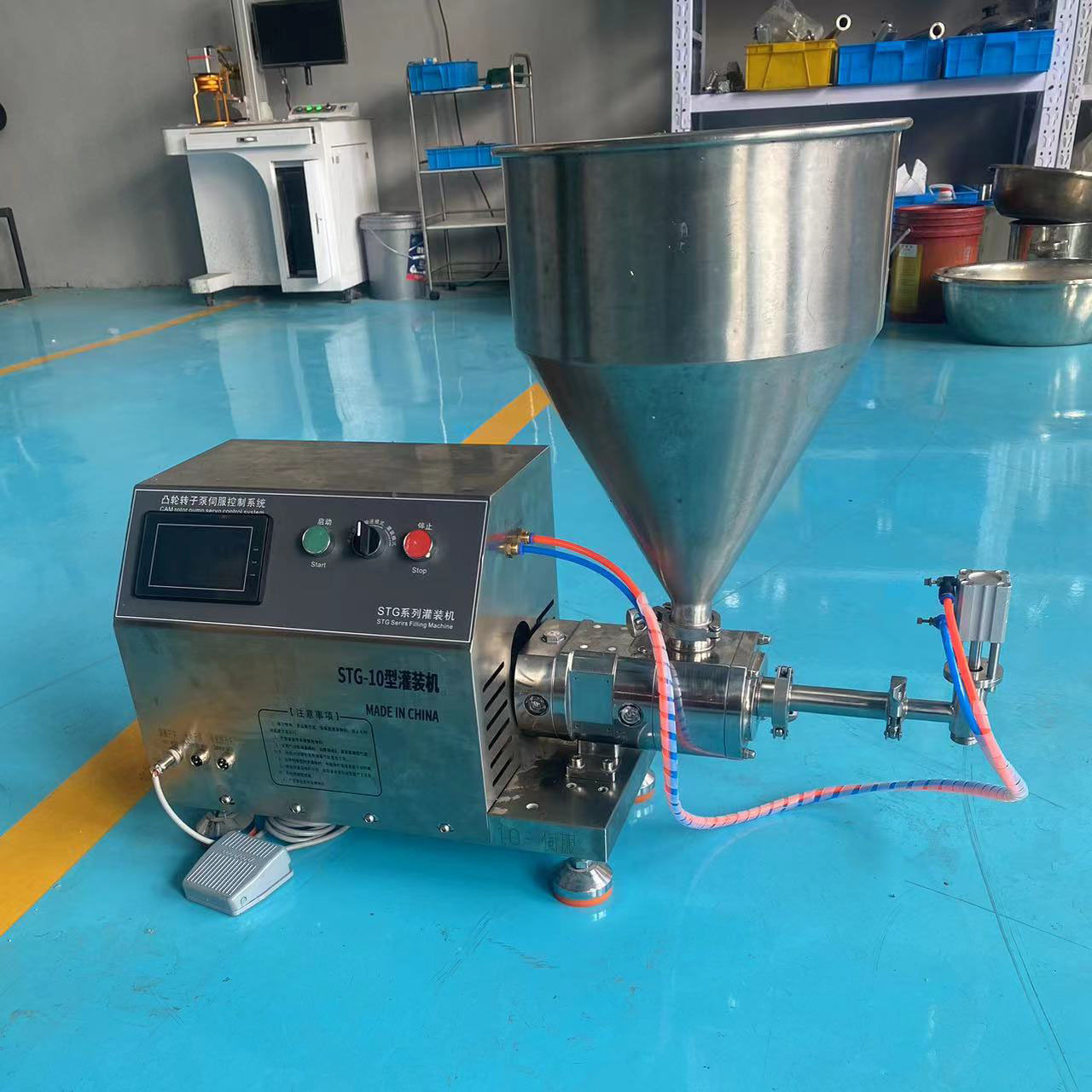

product details

The twin-screw conveying pump filling machine is a device that combines twin-screw conveying pump technology to achieve precise material filling. The following is a specific introduction:

working principle

It is mainly composed of twin-screw, pump body, feed inlet, discharge outlet, and driving device. Twin screws interlock and rotate within the pump body, forming sealed chambers between the screws and the pump body, as well as between two screws, as the screws rotate. At the feed inlet end, as the screw rotates, the volume of the sealed chamber gradually increases, forming a low-pressure zone that sucks the material to be filled into the chamber; Then, as the screw continues to rotate, the material is pushed along the axial direction. At the discharge port end, the chamber volume gradually decreases, generating high pressure, and the material is accurately poured into the packaging container.

characteristic

High precision filling: By precisely controlling parameters such as the speed and rotation angle of the twin-screw, precise control of the filling volume can be achieved, and filling errors can be controlled within a very small range to meet strict filling volume standards for various products.

Wide material adaptability: It can handle a variety of materials with different properties, including low viscosity liquids (such as water, beverages, etc.), high viscosity semi fluids (such as sauces, pastes, etc.), and materials containing certain particles (such as fruit juice with pulp, etc.), all of which can successfully complete the filling task.

Stable operation: The meshing rotation of the twin-screw is relatively stable, and the vibration and noise generated by the equipment during operation are relatively small. It can also operate stably for a long time, reducing equipment downtime due to malfunctions and helping to improve production efficiency.

Good self-priming ability: With a certain degree of self-priming performance, even if there is some air inside the pump body during initial start-up, it can quickly suck in materials and start normal filling operations.

application area

Food and beverage industry: used for filling beverages, juices, milk, various sauces and other products, ensuring the quality of product filling and packaging aesthetics.

Chemical industry: Filling different chemical materials such as paint, coatings, inks, and chemical reagents to ensure the efficiency and accuracy of the filling process in chemical production.

The pharmaceutical industry: meets the filling requirements of products such as drugs and health products for precision and hygiene conditions, and its structural design is also easy to clean and disinfect, in compliance with pharmaceutical industry standards.

Daily chemical industry: it can fill shampoo, bath gel, lotion and other daily chemical products to help efficient packaging and production of daily chemical products